Free Download Pharmaceutical Engineering Notes in pdf – Bpharm 3rd Semester. High quality, well-structured and Standard Notes that are easy to remember.

Welcome to Pharmdbm.com

Pharmdbm provides standard or well-structured Notes for Bpharm students. The notes are free to download. Each semester notes of Bpharm are available on www.pharmdbm.com.

In this post you can download notes of Pharmaceutical Engineering (BP304T). All units are available to download for free.

Pharmaceutical Engineering Notes Unit 1 – 5

UNIT – 1

Flow of fluids, Size reduction, Size separation

UNIT – 2

Heat transfer, Evaluation, Distillation

UNIT – 3

Drying and Mixing

UNIT – 4

Filtration and Centrifugation

UNIT – 5

Materials of pharmaceutical plant construction, Corrosion and its

prevention

Syllabus of Pharmaceutical Engineering (BP304T)

UNIT – 1

Flow of fluids: Types of manometers, Reynolds number and its significance, Bernoulli’s theorem and its applications, Energy losses, Orifice meter,

Venturimeter, Pitot tube and Rotometer.

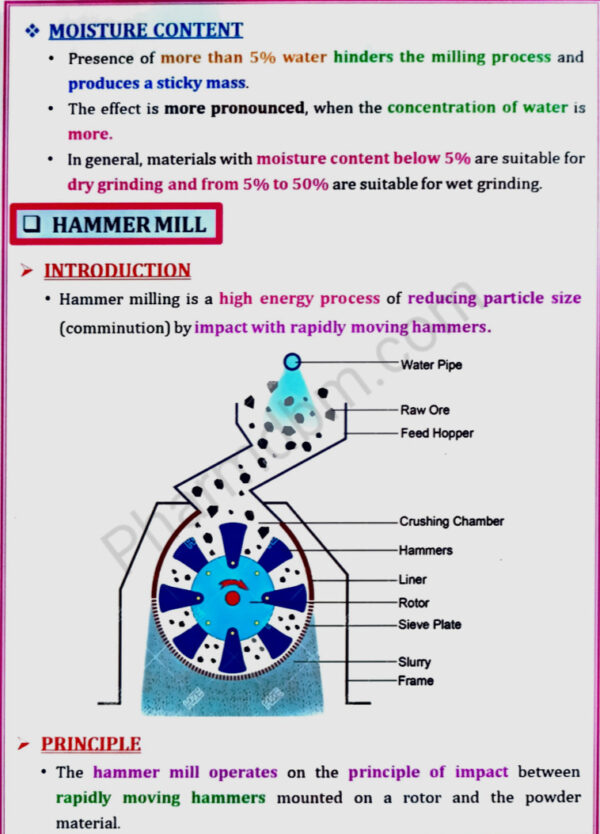

Size Reduction: Objectives, Mechanisms & Laws governing size reduction,

factors affecting size reduction, principles, construction, working, uses, merits and

demerits of Hammer mill, ball mill, fluid energy mill, Edge runner mill & end

runner mill.

Size Separation: Objectives, applications & mechanism of size separation,

official standards of powders, sieves, size separation Principles, construction,

working, uses, merits and demerits of Sieve shaker, cyclone separator, Air

separator, Bag filter & elutriation tank

UNIT – 2

Heat Transfer: Objectives, applications & Heat transfer mechanisms. Fourier’s

law, Heat transfer by conduction, convection & radiation. Heat interchangers &

heat exchangers

Evaporation: Objectives, applications and factors influencing evaporation,

differences between evaporation and other heat process. principles, construction,

working, uses, merits and demerits of Steam jacketed kettle, horizontal tube

evaporator, climbing film evaporator, forced circulation evaporator, multiple

effect evaporator& Economy of multiple effect evaporator.

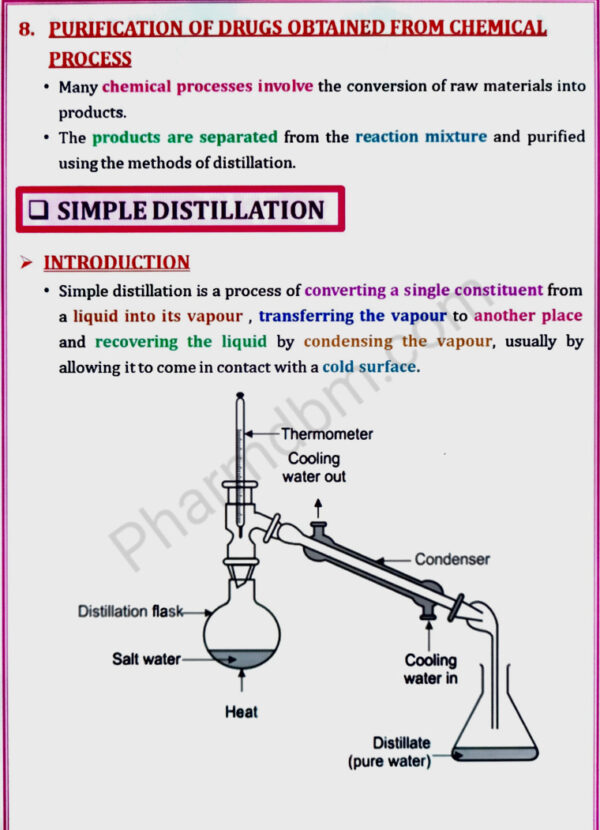

Distillation: Basic Principles and methodology of simple distillation,flash

distillation, fractional distillation, distillation under reduced pressure, steam

distillation & molecular distillation

UNIT – 3

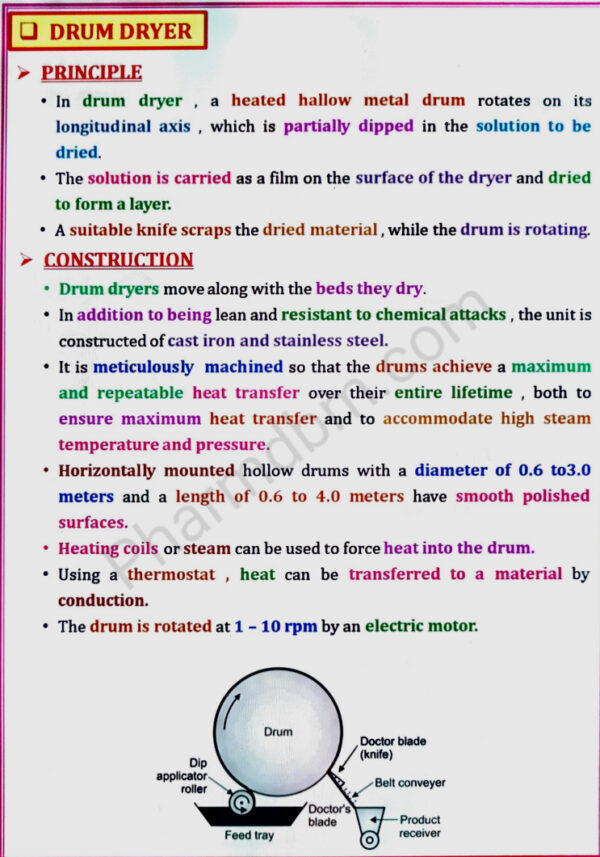

Drying: Objectives, applications & mechanism of drying process, measurements

& applications of Equilibrium Moisture content, rate of drying curve. principles,

construction, working, uses, merits and demerits of Tray dryer, drum dryer spray

dryer, fluidized bed dryer, vacuum dryer, freeze dryer

Mixing: Objectives, applications & factors affecting mixing, Difference between

solid and liquid mixing, mechanism of solid mixing, liquids mixing and

semisolids mixing. Principles, Construction, Working, uses, Merits and Demerits

of Double cone blender, twin shell blender, ribbon blender, Sigma blade mixer,

planetary mixers, Propellers, Turbines, Paddles & Silverson Emulsifier,

UNIT – 4

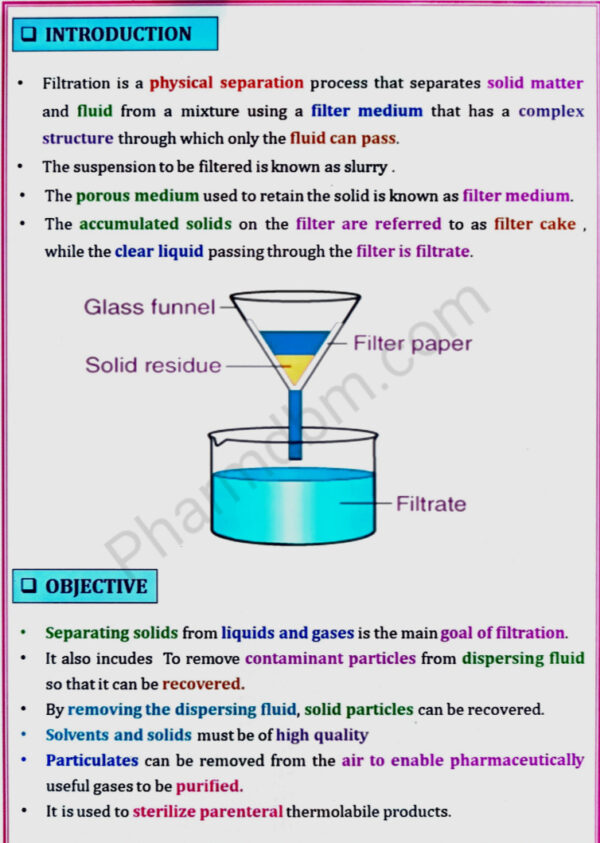

Filtration: Objectives, applications, Theories & Factors influencing filtration,

filter aids, filter medias. Principle, Construction, Working, Uses, Merits and

demerits of plate & frame filter, filter leaf, rotary drum filter, Meta filter &

Cartridge filter, membrane filters and Seidtz filter.

Centrifugation: Objectives, principle & applications of Centrifugation,

principles, construction, working, uses, merits and demerits of Perforated basket

centrifuge, Non-perforated basket centrifuge, semi continuous centrifuge & super

centrifuge.

UNIT – 5

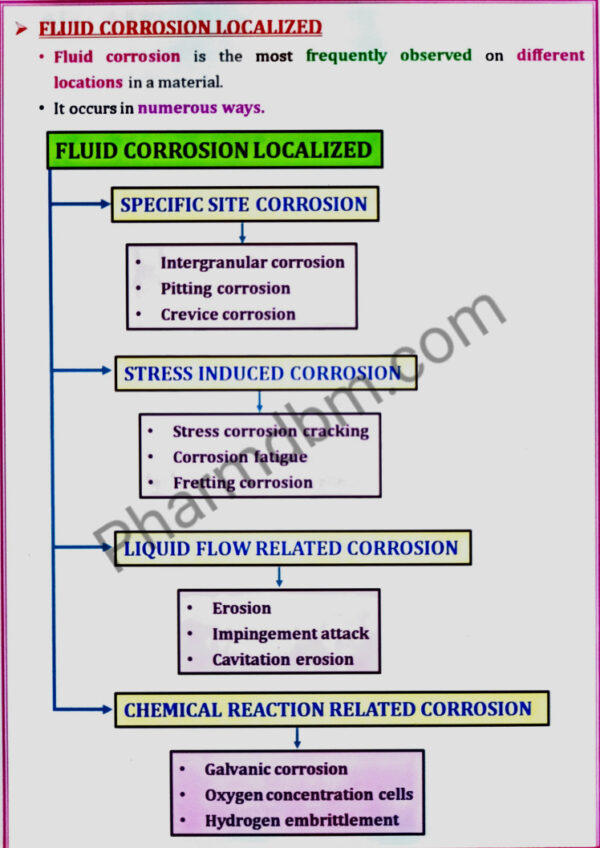

Materials of pharmaceutical plant construction, Corrosion and its

prevention: Factors affecting during materials selected for Pharmaceutical plant

construction, Theories of corrosion, types of corrosion and there prevention.

Ferrous and nonferrous metals, inorganic and organic non metals, basic of

material handling systems.

Scope of Pharmaceutical Engineering

This course is designed to impart a fundamental knowledge on the art and science

of various unit operations used in pharmaceutical industry.

Objectives of Pharmaceutical Engineering

Upon completion of the course student shall be able:

- To know various unit operations used in Pharmaceutical industries.

- To understand the material handling techniques.

- To perform various processes involved in pharmaceutical manufacturing process.

- To carry out various test to prevent environmental pollution.

- To appreciate and comprehend significance of plant lay out design for optimum

use of resources. - To appreciate the various preventive methods used for corrosion control in

Pharmaceutical industries.